All-rounder for a structured data organization

Forget the chaos in the filing system and manage all data from product development and the product lifecycle in one place. Completely documented and digitally managed, from the creation, production and quality control to the acceptance of the parts. Our EDM solution includes document management (DMS), product data management (PDM) and production data management (DNC) in one system, centrally in one place.

It doesn’t matter whether the data is e-mails, CAD data and PDF documents, or production data such as drawings, clamping images or CNC programs.

DMS system

Search and find

Are you looking for a document? Don’t know if it’s the current version? And wondering where the other documents on this topic are?

Even if you haven’t found the document you’re looking for just now, we can reassure you, because there is a solution.

DMS explained

How does our DMS work?

Our EDM solution includes database-supported creation and processing of documents, input and output, distribution and read-only archiving of documents.

A document management system is suitable for the digitization of all types of documents. Papers and documents can be recorded from common sources. By storing documents for the respective process, you always have an overview of all data for each process, even across processes.

You can achieve maximum data and access security to your documents via user roles and authorizations. This is how we pave the way for you to end-to-end digital document management.

EDM project start

We start with what you already have

After the installation, we start immediately with the configuration together with you. It is helpful here if you have already introduced a quality management system that describes the control of documents and records. So we don’t start from scratch. We support you in the organizational determination of employee and group authorizations for access to documents. Your DMS is configured and ready to use in just a few hours.

DMS in full

EVOjetstream DMS

in the fact check

- Manage data and documents for the entire company

- Classify documents individually

- Provide information and data paperless via app

- Access and modification rights for individual users and groups

- Lock and release documents, data & file statuses

- Control overwrite and change protection

- Archive files automatically

- Index documents by full text

- Find data and documents quickly

PDM

Are you already producing or are you still looking?

Despite the ERP system, you need a long time to set up, because you have to gather the necessary information and data from different places – possibly even have to print them out.

This costs you time and causes production downtime.

PDM explained

How does our PDM work?

Product data management (PDM) is the use of software to manage product data and process-related information in a single, centralized system. This information includes CAD data, product information, drawings, manufacturing instructions, quality requirements, set-up information and documents. The right document (up-to-date), in the right format (readable), at the right time (on-demand), in the right place (at the workplace). This way you avoid mistakes and save time and money.

PDM project start

We’ll start with what you already have.

After the installation, we start immediately with the configuration together with you. If your data is stored in file directories in a well-structured manner, the documents can be imported automatically for the product. The assignment to the product and production process can often be derived from the file name.

So we don’t start from scratch and your PDM system is configured and operational in just a few hours. We pay special attention to user-specific authorizations and typing of data and documents.

PDM in full

EVOjet stream PDM

in the fact check

- Data and documents on products and production processes

- Classify documents individually

- Provide information and data paperless via app

- Access and modification rights for individual users and groups

- Lock and release documents, data & file statuses

- Control overwrite and change protection

- Find data and documents quickly

- Archive files automatically

- Manage CAD data for individual parts and assemblies

DNC

Instead of your employees, only the machines are running

Most people are familiar with the frustration that arises when a part is produced from outdated data.

This happens because old data is stored on the machine that is not subject to version control. Or maybe you run from the PC to the machine with the USB stick to save your CNC program on the machine?

There is also a digital and networked solution for this.

DNC explained

How does our DNC work?

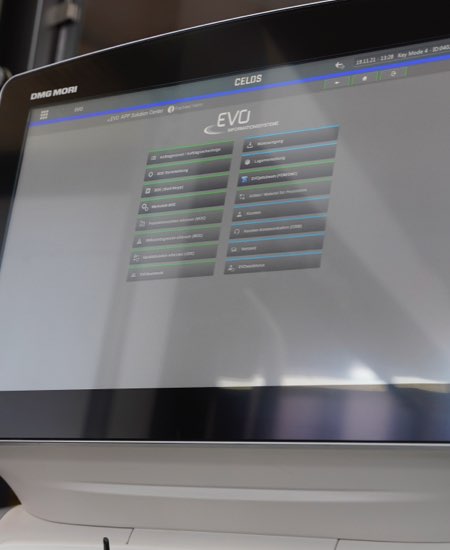

Our DNC software with version control ensures that you only produce your components with approved and up-to-date data. Here, the NC data is transferred on-demand to the machine for processing and deleted again after completion. In this way you ensure a reliable, consistently digital and bidirectional flow of information between your PC and your CNC machines.

Even older CNC machines built after 1990 can be integrated into your machine network and thus become an integral part of your networked production system. Machines with a serial interface can also be retrofitted. In this way you create uniform data management for the entire machine park, with digital and bidirectional data exchange. With our apps with intuitive touch operation, you will develop into a “smart factory”.

As an extension to DNC data transmission, tool measurement data from tool presetting devices can also be transmitted to the machine tool using our patented process without media disruptions. For this purpose, the tool is marked with a barcode, which is simply scanned at a later point in time when it is used in the machine tool and thus causes the tool data to be transferred to the machine.

DNC project start

We prepare well for the installation and setup.

In advance, we determine which machine controls and software versions your machine tools are equipped with. In principle, data can be exchanged with all common machine controls. The most commonly encountered machine controls include the control suppliers Fanuc, Siemens, Heidenhain, Mitsubishi, Mazak, OKUMA and others.

After installation, the appropriate data transmission parameters are set for your machines. Tool presetting devices are also networked here in order to transmit tool measurement data to the machine. Our NC code interpreters are adapted in order to automatically read out the tools from CNC programs for each machine via the algorithm.

Through this preparatory work, the tool lists can also be extracted intelligently and automatically from historical NC data that has been stored for years. So you don’t start from scratch and your DNC system is configured and ready for operation in just a few hours.

DNC in full

EVOjet stream DNC

in the fact check

- Exchange CNC data bidirectionally

- Log CNC data transfers

- Archive CNC programs centrally and in a structured manner

- Back up CNC programs with versioning

- Control program requests from the machines

- Control overwrite and change protection

- Start CNC data transfer via DNC app

- Compare NC programs directly

- Manage data models from the CAD/CAM system

- Automate setup documentation via tablet

- Tool lists from NC code

- Tool monitoring in machines in real time

EVOjet stream FAQ

Everything else you need to know:

Which license models are offered?

EVOjetstream is available for software rental, as well as a purchase software license. The software rental enables an almost risk-free entry into digitization with EVO and with the option of switching to purchasing the license.

How long does it take to network the CNC machines and set up data exchange?

The time required for setup depends on whether a data connection has already been established with the machine via another means (e.g.: network shares, or an old DNC system). If DNC data transmission has not yet been set up, the calculated effort is between one and, in extreme cases, three hours. As soon as we have your machine list, we can better assess the time required. The machine setup, including the tests, takes place on site.

How quickly can paperless production with a digital production folder be implemented?

If you have already stored files in logically structured file directories, your data can be automatically transferred to the PDM system. If this is not the case, you can store the files in EVOjetstream instead of in the file explorer with the same effort with each new order or each new component. With this implementation strategy, you are one step closer in your digitized production day by day. After the instruction and classification of your documents, you are immediately able to use the EVO apps in production on PCs, tablets or the machine control.

What types of data can be managed and structured with EVOjetstream?

The EVO data management concept includes all documents and files that you need to manage in your company. You can define the scope individually and functionally as you like and expand it at any time.

What functionality of the EVOjetstream software should you start with?

As soon as you use machine tools in your production and want to save the NC programs reliably, we recommend integrating the DNC system functionality right from the start. Loss of data on machines and outdated CNC programs cause unnecessary costs and can lead to delays in delivery. It is therefore essential to use the DNC functionality.

Can tool measurement data transmission and tool monitoring be retrofitted in the machines? Which machines are suitable?

In most cases, the process-reliable data transmission of tool setting data to the machine can be easily retrofitted. When monitoring the tools in the machines, this general statement is hardly possible. Here it mainly depends on the capabilities of the machine whether this is possible or whether it can be retrofitted by a service call.

How high is the training effort for the employees? How does the training take place?

The operation of the EVO apps in production and on the machines is quickly explained and conveyed. For a basic understanding, we recommend a workshop on the first day of the project to identify your documents, which you want to direct to the machines via authorizations.

How to install the data management software. How much is the effort?

The software is usually installed on your server via remote maintenance. Duration 1 man day for the implementation incl. Preparation and review. The software is distributed to PCs and mobile end devices via an automated installer or the EVOconnect app via the app stores of the respective providers. EVO will not incur any additional costs for you for internal software distribution.

Contact

Data chaos was yesterday, EVO is tomorrow

If you have the feeling that something has to change, then please let our digitization experts advise you.

25 years digital

This year we celebrate 25 years of EVOlution

For over 25 years we have been helping our customers, from small to large, to use digitization for their businesses.

We have implemented well over a thousand customer projects and we are proud of our long-standing business relationships with our customers and partners.